1. Overview of Power Bank Shell Materials

The material of a power bank’s shell influences both its aesthetic appeal and its functional aspects like durability and heat dissipation. Understanding these differences can guide consumers in making more informed choices.

2. Plastic Shells

ABS Plastic Shells

ABS plastic is a popular choice for power bank shells because it is lightweight and affordable. It offers good impact resistance and flexibility, contributing to the power bank’s durability.

Pros:

- Lightweight

- Budget-friendly

- Durable

Cons:

- Moderate heat dissipation

- Prone to scratching

PC Plastic Shells

Polycarbonate (PC) plastic provides greater strength and impact resistance than ABS, making it a common material in premium power banks.

Pros:

- High strength

- Excellent impact resistance

- Heat-resistant

Cons:

- Higher cost

3. Metal Shells

Aluminum Alloy Shells

Aluminum alloy is another frequently used material for power bank shells, valued for its superior heat dissipation and robustness.

Pros:

- Excellent heat dissipation

- Strong and durable

- Premium appearance

Cons:

- Heavier

- More expensive

Stainless Steel Shells

Stainless steel shells are known for their durability and superior corrosion resistance compared to aluminum alloy.

Pros:

- Extremely durable

- Corrosion-resistant

- High-end look

Cons:

- Heavier

- Highest cost

4. Other Materials

Carbon Fiber Shells

Carbon fiber is an emerging material for power bank shells, offering a combination of lightweight and high strength, making it suitable for premium products.

Pros:

- Extremely lightweight

- High strength

- Durable

Cons:

- Very expensive

Wooden Shells

Wooden shells, although uncommon, appeal to users who value unique textures and eco-friendliness.

Pros:

- Distinctive appearance

- Environmentally friendly

Cons:

- Vulnerable to moisture damage

- Higher cost

5. Conclusion

Choosing the right shell material for your power bank requires balancing factors like cost, weight, heat dissipation, and durability. Plastic shells are ideal for those looking for lightweight and cost-effective options, while metal shells are suited for users prioritizing heat dissipation and longevity. For those seeking a unique, premium experience, materials like carbon fiber and wood offer appealing alternatives.

By understanding the characteristics and advantages of different power bank shell materials, you can make a more informed decision to enhance your user experience.

We hope this article has been helpful. If you have any questions or would like to know more about power banks, please leave a comment below, and we’ll respond as soon as possible.

]]>1. Overview of Battery Cell Materials

Battery cells play a pivotal role in the functionality and dependability of power banks. Different materials are used in these cells, each bringing unique attributes to the table.

2. Lithium-Ion (Li-ion) Battery Cells

What are Lithium-Ion Battery Cells?

Lithium-ion cells are widely used in power banks, known for their high energy density and durability.

Composition:

- Cathode: Typically made from materials like lithium cobalt oxide, lithium manganese oxide, or lithium nickel manganese cobalt oxide.

- Anode: Generally composed of graphite.

- Electrolyte: Consists of lithium salts in organic solvents.

Common Models:

- 18650: A standard size (18mm diameter, 65mm length) offering a good balance between capacity and output.

- 21700: Larger than the 18650 (21mm diameter, 70mm length), providing higher capacity and better efficiency.

Pros:

- High energy density

- Long lifespan

- Low self-discharge

Cons:

- Higher cost

- Safety concerns if mishandled

Applications in Power Banks:

Commonly used in a variety of power banks due to their balance of performance and cost.

3. Lithium Polymer (Li-Po) Battery Cells

What are Lithium Polymer Battery Cells?

Li-Po cells utilize a polymer electrolyte, offering flexibility in form.

Composition:

- Cathode/Anode: Similar to lithium-ion cells.

- Electrolyte: Polymer-based.

Common Models:

- 606090: A rectangular cell (60mm x 60mm x 90mm) known for its high capacity and thin design.

- 1260100: Larger and more capacious, with dimensions of 12mm x 60mm x 100mm, ideal for slim power banks.

Pros:

- Lightweight and versatile

- Safer than Li-ion

- Customizable shapes

Cons:

- More expensive

- Slightly lower energy density

Applications in Power Banks:

Favored for thin, lightweight models.

4. Lithium Iron Phosphate (LiFePO4) Battery Cells

What are Lithium Iron Phosphate Battery Cells?

Known for thermal stability and safety, LiFePO4 cells are reliable and long-lasting.

Composition:

- Cathode: Lithium iron phosphate.

- Anode: Graphite.

- Electrolyte: Similar to other lithium-based batteries.

Common Models:

- 26650: A cell with a 26mm diameter and 65mm length, offering high capacity and stable output.

- 32700: Larger (32mm diameter, 70mm length), with greater capacity and durability.

Pros:

- Excellent safety and thermal stability

- Long cycle life

- Good high-temperature performance

Cons:

- Lower energy density

- More expensive

Applications in Power Banks:

Ideal for high-capacity, heavy-duty power banks.

5. Emerging Battery Technologies

Graphene Battery Cells

Graphene batteries offer high conductivity and rapid charging potential.

Pros:

- Superior conductivity

- Fast charging

- High durability

Cons:

- Still under development

- High production costs

Solid-State Battery Cells

These replace liquid electrolytes with solid ones, enhancing energy density and safety.

Pros:

- Higher energy density

- Improved safety

- Longer lifespan

Cons:

- Technological challenges

- High initial costs

Zinc-Air Battery Cells

Using air as a reactant, these batteries provide high energy density at a lower cost.

Pros:

- High energy density

- Cost-effective

- Environmentally friendly

Cons:

- Limited recharging

- Complex air management

6. Conclusion

The type of battery cell material and model in a power bank greatly affects its performance, safety, and price. Lithium-ion and lithium polymer cells are most common, each with their own benefits. Models like 18650 and 21700 for Li-ion, or 606090 and 1260100 for Li-Po, offer distinct advantages depending on usage. Emerging technologies like graphene and solid-state batteries promise even better performance in the future.

Understanding these battery cell materials and models will help you choose the power bank that best suits your needs.

If you found this guide useful or have any questions, feel free to reach out in the comments below. We’re here to help!

]]>Automatic Solder Paste Printer: Setting the Stage for Excellence

Leading Bluetimes’ SMT assembly line is the automatic solder paste printer. This high-precision machine applies solder paste to PCB pads with exceptional uniformity and accuracy, laying the groundwork for secure, dependable connections between electronic components.

Solder Paste Inspection (SPI) Machine: Ensuring Quality at Every Step

Following the printing process, the SPI machine carefully checks the thickness, consistency, and placement of the solder paste. This critical quality control measure guarantees that each detail meets the highest standards, preventing potential issues that could affect the final product.

Pick & Place Machine: Precision in Every Placement

At the core of Bluetimes’ SMT assembly line is the pick-and-place machine. Operating with incredible speed and precision, it selects tiny electronic components from feeders and places them perfectly onto PCBs. This vital process ensures the circuitry is precisely arranged, preparing it for the next phase.

Reflow Soldering: Creating Strong, Reliable Bonds

Reflow soldering is the process that unifies the carefully positioned components into a cohesive, functioning unit. By meticulously controlling the temperature, the reflow oven melts the solder paste, enabling the components to bond securely to the PCB. As the connections cool, they harden into a robust foundation for the electronic device.

Automated Optical Inspection (AOI): Finalizing Quality Assurance

Finally, the AOI system conducts an in-depth scan of the assembled PCBs using high-resolution cameras and advanced image processing technology. This comprehensive inspection detects any defects, such as missing or misaligned components, polarity errors, or inadequate soldering, ensuring the highest level of quality in the final product.

]]>

The SMT Process at UUK

- Solder Paste Application: The first step in the SMT process is the application of solder paste onto the PCB. This paste acts as an adhesive, ensuring that components stay in place during the soldering process. At UUK, we use high-precision stencil printers to apply the solder paste, guaranteeing a consistent and even coating.

- Component Placement: Once the solder paste is applied, the PCB moves to the pick-and-place machines. These machines are equipped with advanced vision systems that accurately place tiny electronic components onto the board at high speed. UUK’s SMT workshop is equipped with the latest pick-and-place technology, ensuring that each component is placed with pinpoint accuracy.

- Reflow Soldering: After the components are placed, the PCB passes through a reflow oven. This oven heats the board to a specific temperature, causing the solder paste to melt and form a strong, conductive bond between the components and the PCB. Our reflow ovens are carefully calibrated to ensure optimal soldering, preventing issues like cold solder joints or component damage.

- Inspection and Quality Control: Quality is our top priority at UUK. After soldering, each PCB undergoes rigorous inspection using Automated Optical Inspection (AOI) systems. These systems check for any defects, such as misaligned components, soldering issues, or missing parts. If any issues are detected, the PCB is flagged for rework or rejection, ensuring that only the highest quality boards make it to the next stage of production.

- Testing and Final Assembly: Once the PCB passes inspection, it undergoes a series of functional tests to ensure that all components are working correctly. After passing all tests, the PCBs are integrated into the final power bank assembly, where they undergo further testing and quality checks.

Why UUK’s SMT Workshop Stands Out

- Advanced Equipment: UUK invests in the latest SMT equipment to ensure precision and efficiency in every step of the production process.

- Expert Team: Our highly skilled engineers and technicians bring years of experience in SMT manufacturing, ensuring that every power bank meets our rigorous standards.

- Commitment to Quality: Every PCB produced in our SMT workshop undergoes multiple inspections and tests, reflecting our commitment to delivering only the best products to our customers.

By leveraging advanced SMT technology and stringent quality control measures, UUK ensures that each power bank we produce is reliable, efficient, and built to last. This dedication to excellence is what makes UUK a trusted name in the power bank industry.

]]>

The Key Life Test is used to evaluate the durability of buttons on a power bank. This test simulates repeated pressing of the buttons to ensure they can withstand a specified number of cycles without failure. The testing process involves a mechanical apparatus that repeatedly presses the buttons at a controlled force and speed until the set cycle count is reached. The result helps determine the longevity of the buttons under normal use conditions.

Overcharge Test

The Overcharge Test assesses the safety of the battery cell when charged beyond its maximum voltage. This test involves charging the battery cell to a voltage higher than its rated capacity to monitor its behavior under extreme conditions. The primary goal is to ensure that the battery does not overheat, swell, or catch fire. This test is crucial for ensuring the safety of the power bank during accidental overcharging scenarios.

Overdischarge Test

The Overdischarge Test checks the battery cell’s performance when discharged beyond its minimum voltage limit. The battery is intentionally discharged to a voltage lower than the manufacturer’s specified cutoff to observe its reaction. The test ensures that the battery can handle deep discharges without causing damage or reducing its lifespan, thus safeguarding the power bank’s overall performance.

Short-Circuit Test

The Short-Circuit Test evaluates the battery cell’s response to a direct short circuit. During this test, the battery is deliberately short-circuited by connecting its positive and negative terminals with minimal resistance. The test monitors the cell for any hazardous reactions such as overheating, fire, or explosion. This test is critical for ensuring that the power bank remains safe even in the event of a short circuit.

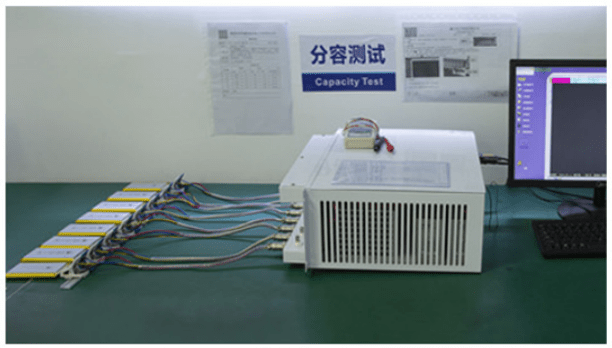

Capacity Sorting Test

The Capacity Sorting Test measures and categorizes battery cells based on their capacity. Each cell is charged and discharged under controlled conditions, and its capacity is measured to determine its suitability for use in power banks. Cells with similar capacities are grouped together to ensure consistent performance in the final product. This test is essential for maintaining quality control and ensuring that the power bank delivers the advertised capacity.

High and Low Temperature Test

The High and Low Temperature Test examines the power bank’s performance across a range of extreme temperatures. The power bank is subjected to both high and low temperatures to assess its functionality, charging efficiency, and safety in different environmental conditions. This test ensures that the power bank operates reliably whether it’s used in very hot or cold climates.

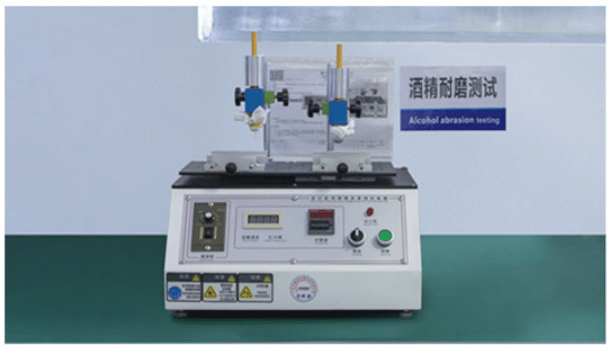

Alcohol Wear Test

The Alcohol Wear Test evaluates the resistance of the power bank’s surface to wear caused by alcohol-based cleaning agents. A cloth soaked in alcohol is rubbed against the surface of the power bank to simulate cleaning. The test checks for any discoloration, damage, or degradation of the surface material. This test is important for ensuring that the power bank maintains its appearance and durability even after frequent cleaning.

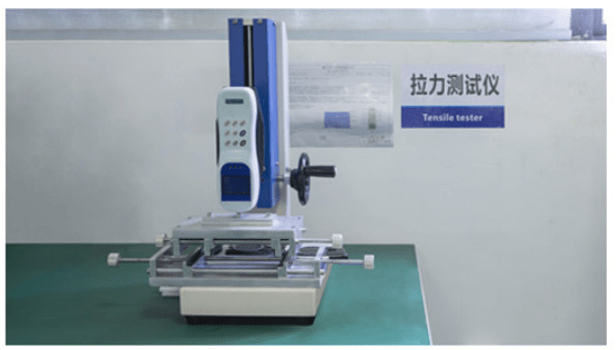

Pull Test

The Pull Test assesses the strength of the power bank’s connectors, such as USB ports and attached cables. A tensile force is applied to these connectors to ensure they can withstand a certain amount of pull without becoming detached or damaged. This test is crucial for ensuring the durability and reliability of the power bank’s external connections during regular use.

Salt Spray Test

The Salt Spray Test evaluates the corrosion resistance of the power bank, especially its metallic components. The power bank is exposed to a salt-laden mist in a controlled chamber for a specified duration. After the test, the power bank is inspected for any signs of corrosion or rust. This test is important for ensuring the longevity of the power bank in humid or coastal environments.

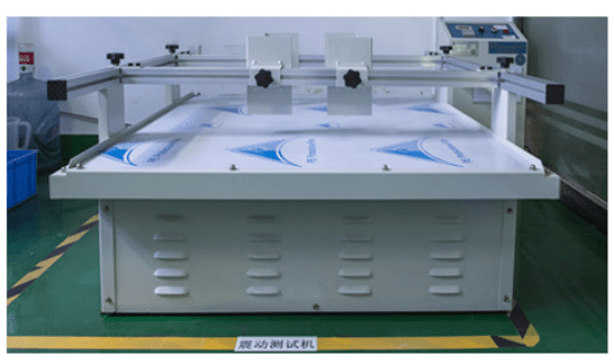

Vibration Test

The Vibration Test assesses the power bank’s ability to withstand vibrations during transportation or daily use. The power bank is placed on a vibrating platform that simulates different levels of vibration over a set period. This test ensures that the internal components of the power bank remain secure and functional despite exposure to vibrations.

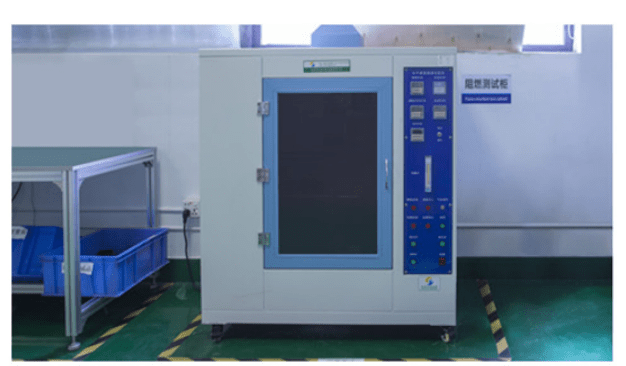

Flammability Test

The Flammability Test determines the power bank’s resistance to catching fire when exposed to high temperatures. During this test, parts of the power bank are exposed to a flame to assess how quickly they ignite and how the fire spreads. The goal is to ensure that the power bank’s materials are flame-retardant, reducing the risk of fire in case of a malfunction.

Advantage of Manufacturing → Factory direct, quality assurance, best price

International Sourcing → Strict quality inspection for raw-material incoming

OEM/ODM Advantage → UUK.served over 1,000 clients to customize products.

Service Network Advantage → Professional sales team with 24 hours quick response.

Equipment Advantages → International standards of production equipment to ensure quality

Certified Advantages → ISO9001,BSCI, CE, FCC, EMC, ROHS etc.

Enviromental Advantages → Products through Rohs test, 100% meet with EU standards.

Quality Advantages → 100% inspection before delivery to ensure that each factory’s products

Cost Advantages → Direct production part and material purchasing.

Service Advantage → Sample only 1days, lead time within 3days, no MOQ.

Price Advantage → Commitment of UUK.: the same quality with lowest price

]]>